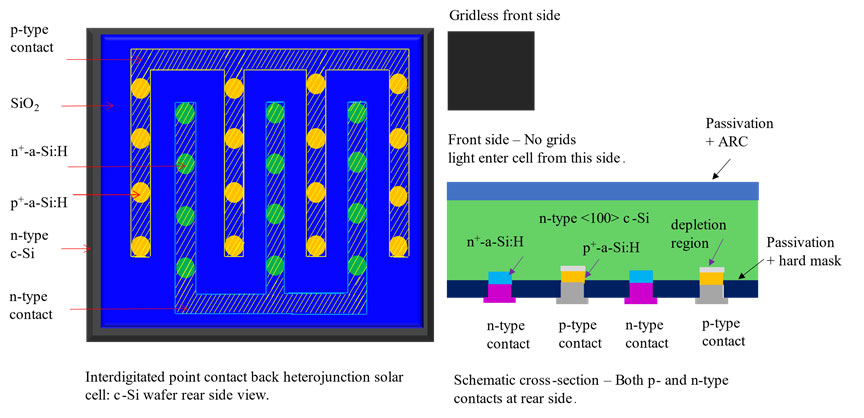

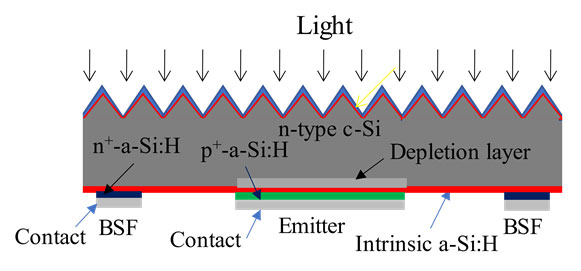

High-efficiency c-Si based interdigitated point contact back heterojunction solar cells

Journal of Materials Science: Materials in Electronics, 28 (2017) 9697–9703.

Solar Energy, 105 (2014) 109–115.

Solar Energy Materials & Solar Cells, 109 (2013) 199–203.

Materials Express, 2 (2012) 177-196.

At GVN SolarPower, for energy applications, we are dedicated to developing efficient and affordable solar cell technologies through research and development.

132 92 Ave, Skye Pl.

Surrey V3V 6T6

Vancouver BC, Canada

+1 604 203 2409

jkr@gvnsolarpower.com

careers@gvnsolarpower.com

While contacting us by email, please send a Cc to gvnsolarpower@gmail.com

Copyrights © 2023 GVN SolarPower Inc. Developed & Hosted by YOGA’S IT Solutions.