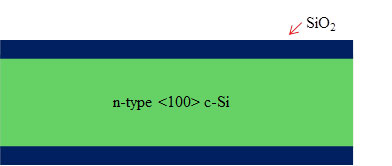

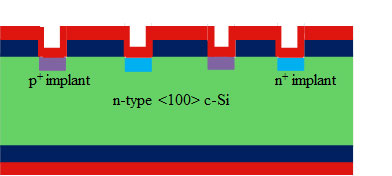

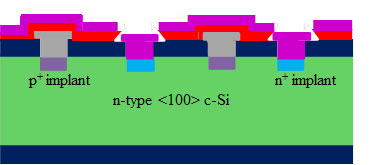

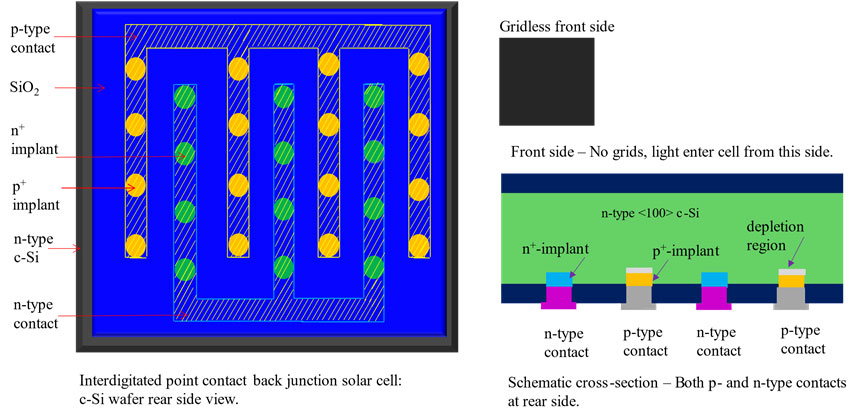

Ion implantation is a low temperature process used for p-type and n-type doping at the rear side of c-Si wafers to fabricate back junction c-Si solar cells. Doping uniformity of less than 1% variation can be achieved. Dopant concentration, penetration depth and spread range are better controlled than diffusion method used for c-Si solar cells.

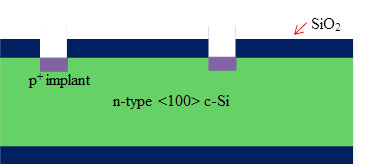

Before going to actual fabrication, several process simulations were performed to determine an ideal ion beam energy and implant dose which determines junction (implant) depth and dopant concentration respectively.

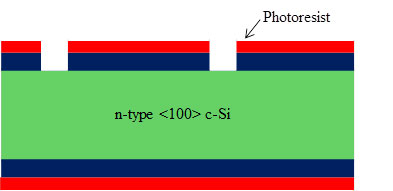

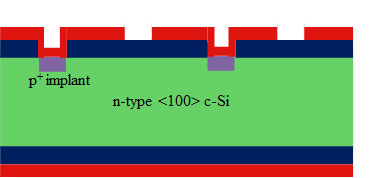

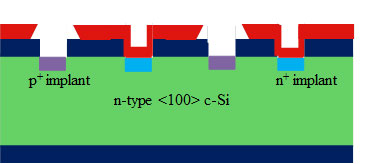

After implantation, resist removed.

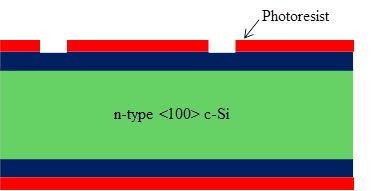

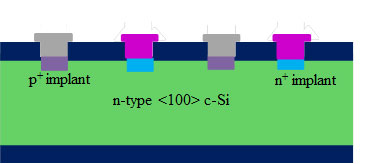

Now, resist coated on both sides. Photoresist is required at the rear side to avoid process induced damages.

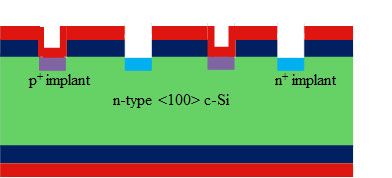

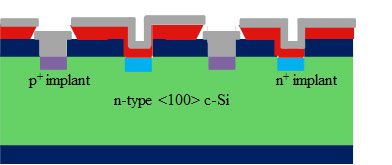

Mask 3: Patterned at the front side for metal deposition. While developing, acetone remove the resist in the unexposed areas.

Metal deposited ~0.5 μm.

After lift-off photoresist, p-type metal contact is completed.

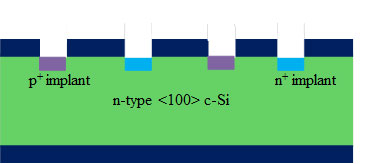

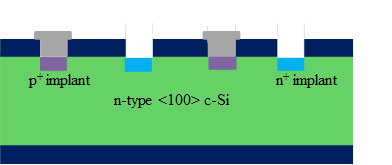

Mask 4: Resist coated and patterned for n-type contact.

Lift-off resist and metal over the resist. Now n-type metal contact completed.

Prog. Mat. Sci. 82 (2016) 294-404.

At GVN SolarPower, for energy applications, we are dedicated to developing efficient and affordable solar cell technologies through research and development.

132 90 Ave, Skye Pl.

Surrey V3V 6T6

Greater Vancouver BC, Canada

+1 604 203 2409

jkr@gvnsolarpower.com

with a Cc to: gvnsolarpower@gmail.com

Copyrights © 2023 GVN SolarPower Inc. Developed & Hosted by YOGA’S IT Solutions.